Table of Contents

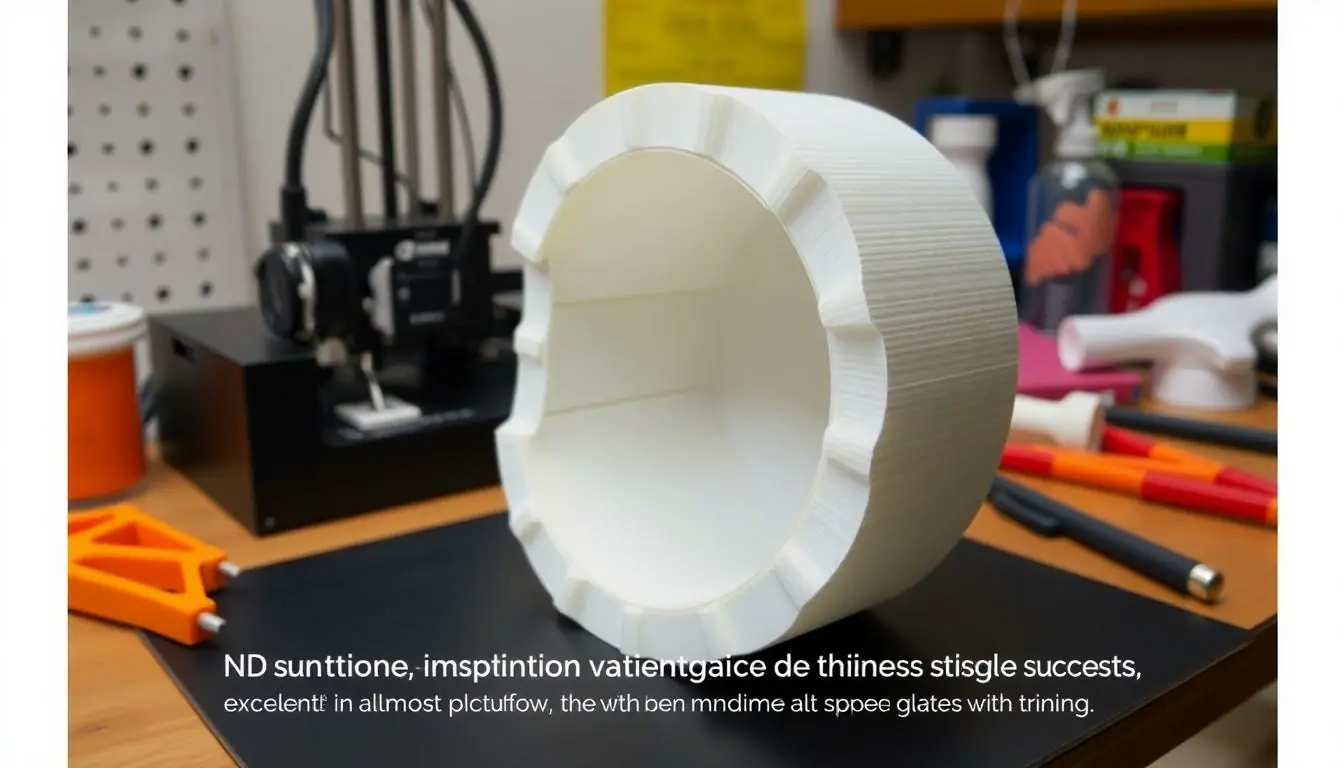

ToggleIn the world of 3D printing, wall thickness can feel like a game of Goldilocks—too thin and your creation crumbles, too thick and you waste material like a kid with a chocolate bar. Finding that sweet spot is crucial for durability and aesthetics. Minimum wall thickness isn’t just a number; it’s the foundation of a successful print.

Whether you’re crafting intricate designs or robust prototypes, understanding the minimum wall thickness can save you from the heartbreak of a failed print. It’s all about balance—achieving strength without sacrificing detail. Dive into the nitty-gritty of this essential concept and discover how to elevate your 3D printing game, one layer at a time. After all, who wants a flimsy masterpiece when you can have a sturdy showstopper?

Overview of Minimum Wall Thickness 3D Printing

Minimum wall thickness plays a vital role in 3D printing, significantly impacting both structural integrity and overall design. Designers must balance durability with material efficiency, which creates a need for precise thickness measurements. Thicker walls generally offer improved strength but also lead to increased material use and longer print times. On the other hand, walls that are too thin cause prints to become fragile, increasing the risk of breakage during handling or use.

Common materials, like PLA and ABS, require different minimum wall thicknesses. For instance, PLA often performs well with a minimum thickness of 1.0 mm, while ABS may need at least 1.5 mm for optimal strength. Understanding specific material properties can lead to better choices regarding wall thickness, ultimately enhancing the functionality of the printed object.

Design software often includes tools to help visualize and adjust wall thickness, improving a project’s overall results. The software prompts designers to analyze their models for weak points, allowing them to assign appropriate thickness throughout.

Evaluating print settings becomes essential when considering minimum wall thickness. Print speed, layer height, and infill density all influence the effectiveness of wall thickness. Incorporating these factors into design from the start leads to more successful prints and fewer failures.

Ultimately, knowledge of minimum wall thickness helps 3D printing practitioners achieve better aesthetics and efficiency in their work. By prioritizing this aspect, they enhance the quality of their prints. Adapting designs based on wall thickness can create stronger, more visually appealing models.

Importance of Minimum Wall Thickness

Minimum wall thickness plays a vital role in 3D printing. Achieving the right thickness ensures durability and efficiency in designs.

Impact on Structural Integrity

Structural integrity depends heavily on minimum wall thickness. Thicker walls generally enhance the strength of prints, reducing the risk of breakage. Designers must balance this benefit with increased material usage and print time. 1.0 mm is suitable for PLA, while ABS typically needs at least 1.5 mm for optimal strength. Identifying the appropriate thickness prevents weak points and failures. Evaluating design choices directly correlates with the longevity and functionality of printed objects. Strengthening critical areas further optimizes the overall performance of the model.

Effect on Print Quality

Print quality faces significant challenges when wall thickness isn’t properly managed. Thin walls often result in sagging or inconsistent surfaces during the printing process. Thicker walls contribute to a stable base for finer details, improving the overall appearance. Layer adhesion also improves when walls maintain appropriate thickness, leading to a more robust finished product. Designers should consider material properties to achieve the best results. Adjusting settings, such as temperature and print speed, can help mitigate potential issues related to wall thickness. Ensuring quality also enhances visual appeal and user satisfaction.

Factors Influencing Minimum Wall Thickness

Understanding the factors influencing minimum wall thickness is crucial for successful 3D printing. Various elements play a significant role in determining the optimal thickness for a given project.

Material Properties

Material properties directly affect minimum wall thickness in 3D printing. Different materials possess unique characteristics that influence their performance. For example, PLA offers good rigidity and flexibility and typically performs with a minimum wall thickness of 1.0 mm. ABS, by contrast, requires a thicker wall, usually around 1.5 mm, to maintain its structural integrity during and after printing. Variations in tensile strength, impact resistance, and thermal stability shape how materials respond to forces. Designers must account for these properties to prevent issues like warping or cracking.

Printer Specifications

Printer specifications significantly impact the achievable minimum wall thickness. Each printer model has unique capabilities, including nozzle size and precision. A larger nozzle diameter might limit the ability to print thinner walls effectively. Layer height settings also affect wall thickness; higher layer heights provide less detail and may lead to less reliable thin walls. Additionally, print speed plays a role in ensuring appropriate adhesion between layers. Different printers handle materials differently, so understanding a specific printer’s limitations is essential for optimal results.

Best Practices for Achieving Minimum Wall Thickness

Achieving the optimal minimum wall thickness involves careful consideration of various factors such as design and slicing settings.

Design Considerations

Designers must ensure models include sufficient wall thickness for strength and aesthetics. Features that include fine details or intricate designs need a balance between thickness and refinement. Evaluating stress points within the model helps prevent weak areas. Designers should also verify that there are no unsupported overhangs, as these increase the risk of failure during printing. Applying fillets or gradual transitions in areas experiencing stress can enhance durability. Using simulation tools for analyzing stress distribution can also be beneficial. Keeping these factors in mind leads to more robust and visually pleasing prints.

Slicing Software Settings

Slicing software plays a pivotal role in controlling wall thickness effectively. Users must adjust settings for layer height and shell thickness to match design specifications. Setting the wall line count appropriately influences strength and surface finish. A minimum of two to three outer walls typically enhances durability. In addition, tweaking parameters such as infill density impacts the overall strength of the printed object. Proper temperature settings optimize material flow and adhesion, influencing the final print’s quality. By paying attention to these slicing settings, individuals ensure better control over their project’s structural integrity.

Understanding minimum wall thickness in 3D printing is vital for achieving strong and aesthetically pleasing designs. By carefully balancing durability and material efficiency designers can significantly enhance their print quality. The right wall thickness not only ensures structural integrity but also prevents common pitfalls like fragility and print failures.

As designers experiment with different materials and printer specifications they’ll find that optimal wall thickness varies. Utilizing design software and simulation tools can further refine their approach allowing for more robust and reliable prints. By prioritizing these considerations designers can elevate their 3D printing projects to new heights.