Table of Contents

ToggleIn a world where everything seems to be getting lighter, faster, and more efficient, titanium 3D printing is the heavyweight champion of innovation. Imagine crafting complex structures with a material that’s as strong as a superhero’s cape but light enough to make a feather jealous. It’s not just a dream—it’s the future of manufacturing.

From aerospace to medical implants, titanium’s unique properties make it the go-to choice for industries that demand durability and precision. But why settle for ordinary when you can print extraordinary? With 3D printing, the possibilities are endless, and the only limit is your imagination (and maybe your printer’s settings). Dive into the fascinating world of titanium 3D printing, where creativity meets cutting-edge technology, and discover how this game-changer is reshaping the way we build.

Overview of 3D Printing Titanium

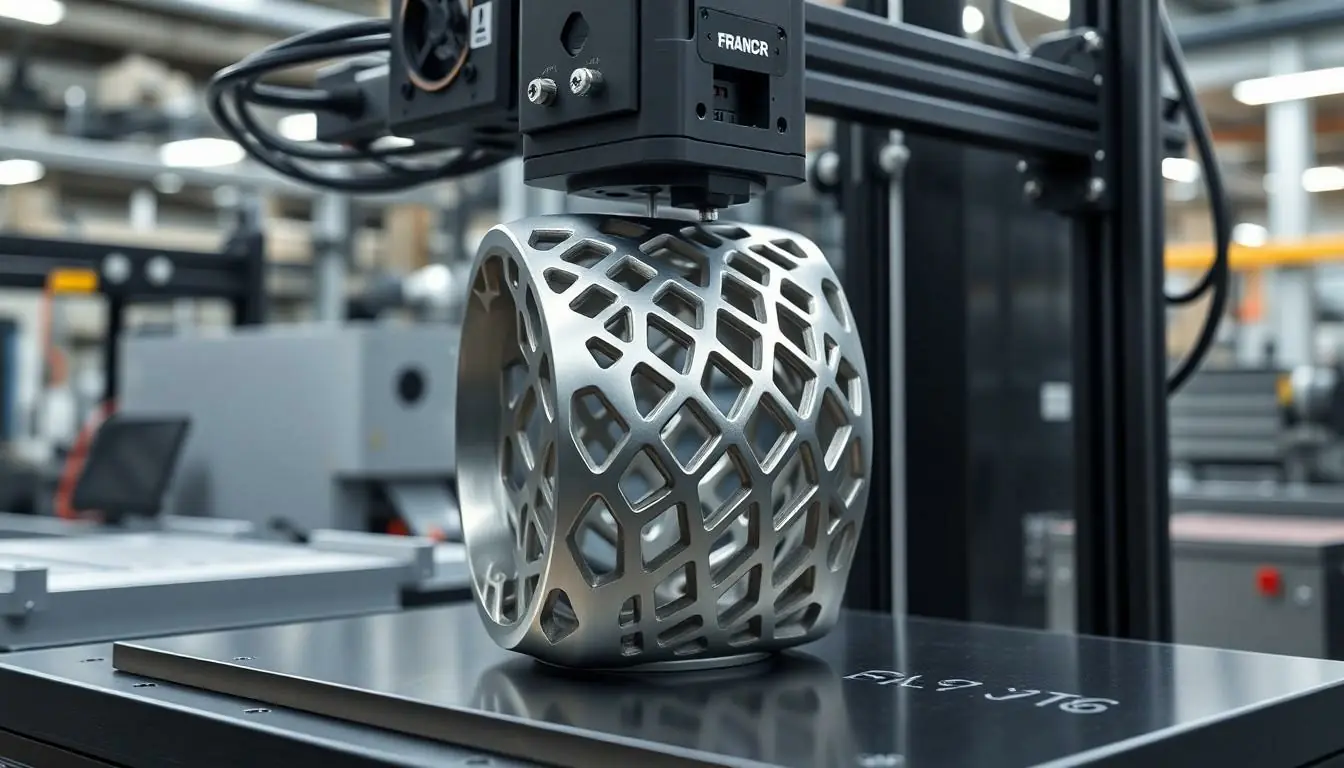

3D printing titanium utilizes advanced technologies to create complex parts and components. This method allows for the production of lightweight and strong structures, ideal for industries such as aerospace, automotive, and healthcare. The process often employs laser melting techniques, which fuse titanium powder layers together to form precise shapes.

Aerospace companies benefit significantly from titanium’s high strength-to-weight ratio. For instance, parts manufactured using 3D printing resist extreme conditions, enhancing aircraft performance and safety. Medical implants also see substantial improvements through this technology. Customized titanium implants can be tailored to fit patients’ anatomical needs, promoting better integration with bone and reducing recovery time.

Titanium’s corrosion resistance further contributes to its appeal in 3D printing applications. Corrosive environments commonly encountered in marine and chemical industries pose fewer risks when using titanium-based components. The adaptability of 3D printing means that manufacturers can produce small batches of specialized items without substantial investment in tooling.

Alloy compositions can also be adjusted in 3D printing to enhance specific properties of titanium. By varying the titanium alloy, manufacturers achieve desired strength, ductility, and resistance to fatigue. As the technology continues to advance, the efficiency and precision of titanium 3D printing are expected to improve further, providing more opportunities for innovative uses.

Industry experts predict robust growth for titanium 3D printing, driven by its numerous advantages. The transformative potential of this technology encourages further exploration of new applications across multiple sectors.

Benefits of 3D Printing Titanium

3D printing titanium offers numerous advantages across various industries. Its unique properties make it a preferred choice for advanced manufacturing.

Lightweight and Strong

Titanium boasts a high strength-to-weight ratio, making it an optimal choice for aerospace applications. Aircraft components manufactured using titanium 3D printing are often lighter yet maintain exceptional strength, leading to improved fuel efficiency. Engineers utilize this characteristic to create parts that withstand extreme conditions without adding unnecessary weight. The result is enhanced overall performance and safety. Additionally, titanium’s mechanical performance under stress is unrivaled, which improves reliability and longevity in demanding environments.

Design Flexibility

3D printing technology allows for unparalleled design freedom with titanium. Complex geometries that were once difficult or impossible to achieve using traditional methods can now be easily created. Manufacturers design intricate internal features and lightweight lattice structures that enhance functionality without compromising structural integrity. Customization becomes more accessible, allowing for tailored solutions that meet specific needs in industries such as medical and aerospace. Designers benefit from rapid prototyping capabilities, enabling faster iterations and reduced time to market.

Applications of 3D Printing Titanium

3D printing titanium has various applications that leverage its unique properties across multiple industries.

Aerospace Industry

Aerospace benefits immensely from titanium 3D printing’s strength and lightweight properties. Aircraft components, such as brackets and structures, achieve significant weight reductions while maintaining structural integrity. The ability to create complex geometries enhances aerodynamics, leading to fuel efficiency improvements. Manufacturers design parts specifically tailored for performance in extreme conditions, making use of titanium’s exceptional resistance to corrosion. Furthermore, production processes can streamline supply chains by enabling on-demand manufacturing, reducing lead times and costs.

Medical Implants

In the medical field, titanium 3D printing transforms the creation of custom implants for patients. Each implant can be designed to match a patient’s unique anatomical structure, promoting better integration with bone. The lightweight nature of titanium minimizes discomfort, while its biocompatibility ensures a lower risk of rejection during recovery. Surgeons benefit from precise fitting, leading to quicker surgical times and improved outcomes. Additionally, advanced customization meets various patient needs, from orthopedic implants to dental applications, thereby enhancing the overall patient experience.

Challenges and Limitations

Titanium 3D printing offers numerous benefits, yet challenges persist that may impede broader adoption across industries.

Material Costs

Material costs for titanium remain high, affecting overall project budgets. The price per kilogram for titanium often surpasses $30, making it more expensive than common metals like aluminum and steel. Significant investments in raw material often discourage small businesses from incorporating titanium 3D printing into their processes. High-quality titanium alloys further increase costs due to their specialized properties. Companies seeking to leverage this technology must carefully evaluate whether the benefits outweigh these expenses.

Technical Expertise

Technical expertise serves as a significant barrier to titanium 3D printing’s adoption. Specialized knowledge in additive manufacturing processes, materials science, and post-processing techniques is essential for successful production. Companies without skilled workers face challenges in ensuring proper printer setup and operational efficiency. Additionally, a lack of established best practices complicates the implementation of titanium 3D printing within their workflows. Achieving optimal results demands investment in training and development, which may deter some organizations from fully embracing this innovative technology.

Future Trends in 3D Printing Titanium

Advancements in 3D printing technology are set to reshape the future of titanium manufacturing. Innovations in materials science enhance the performance characteristics of titanium alloys, leading to superior products. Enhanced printing techniques reduce waste and increase production speed, making titanium parts more accessible.

Notably, integration of artificial intelligence and machine learning into the 3D printing process optimizes parameters for better accuracy and efficiency. Companies utilize AI to analyze design data, ensuring optimal material usage and minimizing resource consumption.

Sustainability becomes a focal point, with industries seeking eco-friendly solutions. Recycling titanium from production waste becomes a viable option, providing a circular economy model. As carbon reduction initiatives gain momentum, sustainable practices in titanium 3D printing align with global efforts.

Customization will continue to drive demand. Personalized implants and components designed specifically for individual needs promote better healthcare outcomes. Manufacturers employ advanced software to create unique designs that meet precise specifications.

Advancements in regulatory frameworks will facilitate broader adoption across multiple sectors. Standardizing practices and certifications enhances trust in 3D printed titanium products. Government bodies strive to ensure safety and reliability in aerospace and medical applications.

Growth projections indicate substantial market expansion. Experts forecast a compound annual growth rate (CAGR) of 20% in the titanium 3D printing sector over the next five years. This anticipated growth reflects increasing interest from both large enterprises and startups investing in titanium technologies.

The future of 3D printing titanium is poised for transformation through technological advancements, sustainability efforts, and customization opportunities.

Titanium 3D printing stands at the forefront of technological innovation. Its unique properties and versatility are reshaping industries from aerospace to healthcare. As advancements continue to emerge the potential for customized solutions and enhanced performance is limitless.

Despite challenges such as high costs and the need for specialized knowledge the future looks bright. With ongoing improvements in materials science and manufacturing processes the adoption of titanium 3D printing is set to accelerate.

This technology not only promises efficiency and sustainability but also paves the way for groundbreaking applications that meet the evolving demands of modern manufacturing. Embracing titanium 3D printing could redefine standards across various sectors.